E-commerce is booming, and with rising rent prices, the desire for speedy deliveries and the growing importance of sustainability in the logistics industry, warehouses are transforming rapidly. In this blog, we’ll explore five major warehousing trends that make logistics processes more efficient, greener and safer:

- Vertical Warehousing

Vertical warehousing is becoming popular. With the rising demand for fast delivery, there’s a growing need for warehouses near crowded cities where space is scarce and costly. This shift has led to the adoption of a new warehouse style that occupies less space in order to cut costs. The development of automation has made vertical warehousing even more practical in today’s “smart” warehouses, where machines help organize items, lift packages to higher spots, and move them around efficiently.

- Smart Shelving

Shelving optimization is not a recent development. The industry has long explored ways to enhance shelving efficiency and simplicity. However, the integration of sensors and data analysis for more efficient inventory and space management is a relatively recent advancement. Smart shelves can monitor inventory levels and alert you when supplies are running low, even if you’re not at the warehouse. Additionally, smart shelving can contribute to sustainability by saving energy through automated lighting control.

- Wearables

Wearable devices like smart glasses and wrist gadgets are gaining popularity in logistics. They help warehouse staff to work more efficient and more safe by decreasing manual labor. For example with barcode scanners that have been around for a long time, staff don’t have to pick up packages to scan. In recent years, wearable scanners have advanced. Now, they can link to smartphones via Bluetooth. The scanners quickly inform workers if there are any errors or mistakes, for example when they’ve chosen the wrong item or selected the wrong amount. These smart wearables with its many features can improve communication among team members, reduce errors, and even assist with training and inventory management.

- Warehouse Management Systems (WMS)

WMS is at the heart of smart warehouses. A WMS is a software that helps companies manage and control daily warehouse operations, from the moment items enter a distribution or fulfillment center until the moment they leave. WMS’ are essential because it gives a team insights by monitoring all the items within their storage. When a customer places an order, the system will immediately check if the product is available. It also helps to keep track of what products sell, so a company can optimize their stock. Besides that, a WMS has the capability to establish processes that make it easier for employees to select items and prepare orders efficiently.

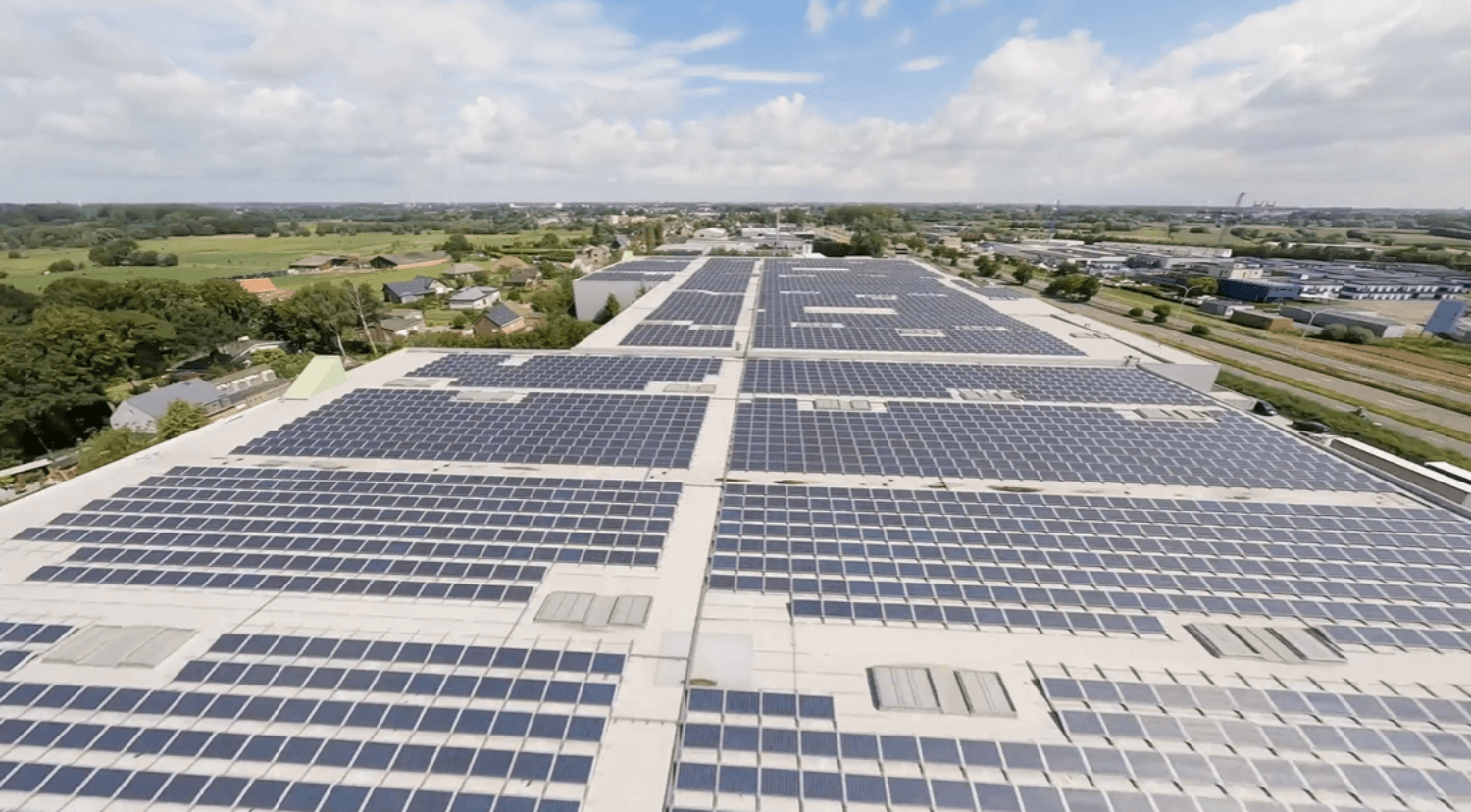

- Green Warehousing

Sustainability is a top priority in the logistics industry, not just for transportation and shipping, but also in terms of warehousing. There are several measures logistics companies are taking to make their warehouses more environmentally friendly. Vertical warehousing, which we mentioned earlier in this blog, is one example. This type of warehouse makes the most of available space, allowing businesses to store more goods in a smaller footprint while reducing energy consumption. Many modern warehouses are upgrading their lighting systems with energy-efficient LEDs and motion sensors, which not only reduces energy consumption but also lowers operational costs. Last, recycling efforts have become an integral part of green warehousing. Warehouses are implementing waste separation programs, which help to avoid (a big portion of) waste ending up in landfills.

In the ever-expanding world of e-commerce, warehouses are undergoing significant transformations. There are These five trends are driving efficiency, sustainability, and safety. They enable warehouses to meet the evolving demands of businesses and customers while also prioritizing environmental responsibility.